Call us: +44 (0)1625 874598 Email us: sales@pumptech.co.uk

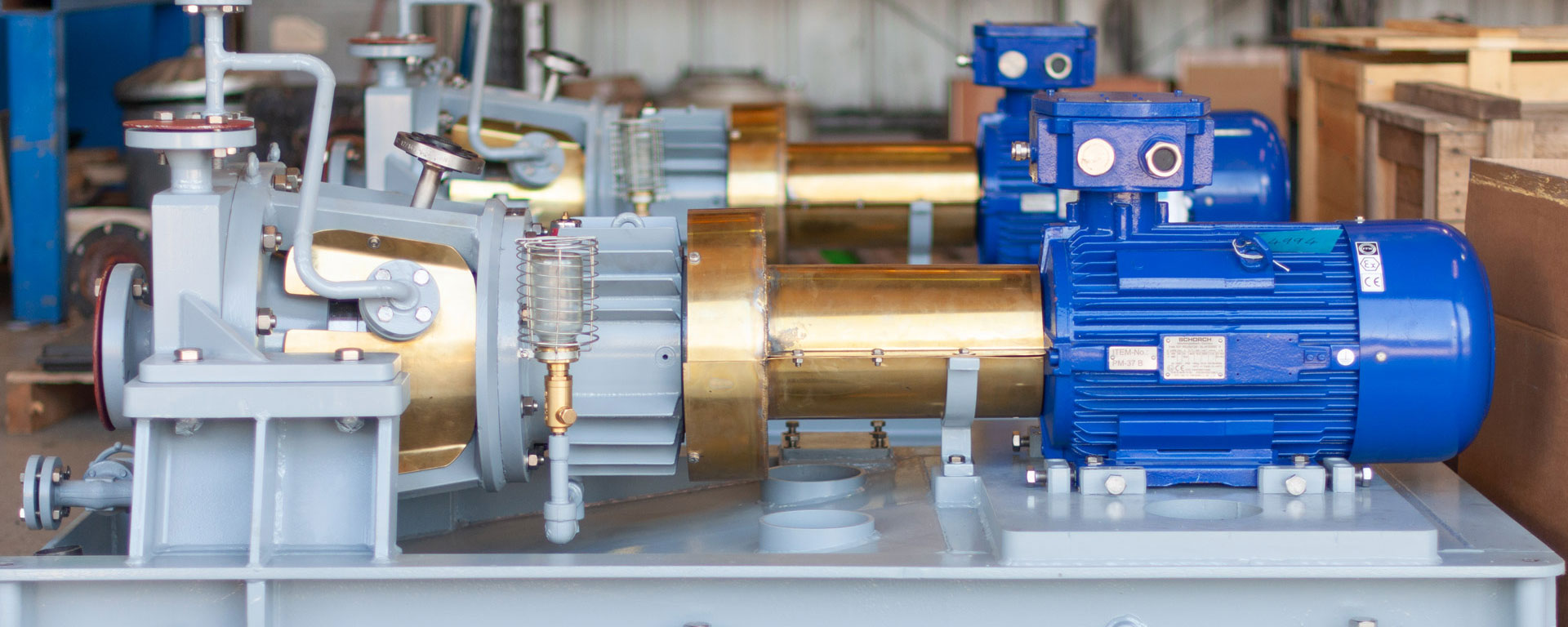

Pumps individually designed for your unique requirements

Specialists in Horizontal and Vertical Centrifugal pumps

Extensive experience with exotic materials

Made in Britain

Exported Worldwide

Experts at solving

customer problems

Units are individually engineered from a proven design base to incorporate customer process requirements – this flexible approach ensures the optimum features essential for a trouble free, low maintenance installation.

A wealth of experience

We have over forty years’ experience working with pumping equipment, producing centrifugal pumps, chemical pumps, corrosion resistant pumps, horizontal and vertical pumps, and many others in a variety of exotic metals and materials such as Titanium, Zirconium, Duplex, PTFE and other non-metallics for a range of demanding applications.

Markets we serve

Oil & Gas

PATS’ range of API 610 pump units are designed and built to order to meet the specific requirements of our customers. The cutting edge design features continue to provide reduced maintenance costs, increased operational life and higher productivity in one of the most challenging industries. Our pumps perform reliably under the most demanding process requirements handling highly volatile hydrocarbons, viscous fluids, and aggressive liquids.

Industrial

Pumps for general industry cover a wide range of equipment designed typically in accordance with ISO 5199 and ANSI B73.1 standards. From horizontal long and close-coupled end suction units to vertical line-shaft and cantilever sump pumps, inline pumps, and vertical turbine pumps, we have a pump that will meet your requirements. A significant number of these units are specifically dimensionally designed as a retrofit to replace old or failing pumps where the pipework and process layout cannot be modified or replaced.

Water

With the continuously increasing challenges faced with global population growth coupled with a significant increase in consumption, PATS can offer a wide range of high efficiency water and wastewater pump systems for domestic, municipal and industrial applications.

Chemical

Having a wealth of experience in the global chemical industry, our pumps are specifically designed to handle a wide range of corrosive and aggressive liquids. We are able to offer an extensive range of design features and corrosion resistant materials to cover most customer requirements. Being designed to order we can also easily incorporate any sealing requirements.

Power

PATS continue to provide engineered solutions to the highest design and quality standards. Modern energy production is a stringent industry with efficiency, emission control and safety requirements being key drivers for power plants. We produce innovative products which continue to exceed our clients’ requirements whilst monitoring the continuously evolving technologies for power generation.

Bespoke Design

At PATS we receive many enquiries for equipment that is simply not commercially available from any standard pump manufacturer. Extensive research and development records enable us to produce uniquely designed pumps for a multitude of customers’ non-standard process requirements, manufactured in any commercially available material for test laboratories/facilities, plastic recycling plants, universities etc. which are all one of a kind and designed and built to meet our customers’ exacting needs.

Their capability is extensive and their approach to providing pumping solutions is first class.

Rob Paul. Senior Mechanical Engineer. United Utilities

I would have no hesitation in recommending the services of a very professional and accommodating outfit such as PATS.”